Recognized by the European Union and Geneva Inventions as a leading innovation in carbon capture technologies.

Capture Efficiency

CO2 Purity

Energy Consumption

CapsoPure™ is the key process used in all our carbon capture systems. It is a 2-step operation to convert industrial flue gas into high purity liquid CO2. The design of the process and the sequence of treatment techniques help achieve a CO2 purity of over 99.9999%, making it suitable for use in most utilization scenarios.

The Process

Industrial flue gas is pumped into the first tower where the removal of SOx and NOx takes place with the help of CapsoS™ chemical solvent.

The flue gas then moves into the second tower where the CapsoC™ chemical solvent is introduced and binds with the CO2 molecules.

The CO2 rich CapsoC™ solvent is then transferred to a heat exchanger and moves into the third tower. Here, the CO2 separates from the heated solvent with a 96% purity and continues its journey in the following purification process.

The Process

Treated flue gas from the previous Concentration step is then treated for water removal and pressurized via a compressor.

It then transfers into the first set of dual towers for deep dehydration treatment using special water removal sorbents.

Next, the treated flue gas enters the second set of dual towers for adsorption treatment using CapsoX physical sorbents. Different sorbents are used to remove different impurities determined by the source of the flue gas.

Finally, the treated flue gas is liquefied and moves into the single distillation tower for the removal of any remaining light weight gas compounds.

The final product is a 99.9999% purity or higher liquid CO2, which is then stored in a product tank, awaiting transportation, utilization, or further processing.

The Process

To expand the utilization capabilities of the recovered CO2, one may choose to apply further processing after the previous step of purification.

One common procedure involves feeding the high purity CO2 from the product tank into a dry ice production machine where the liquid CO2 is compressed into solid CO2 aka dry ice.

The conversion ratio of liquid CO2 to dry ice is normally about 2.5:1 tons. However, this can be improved to 1.2:1 tons by installing a waste CO2 regenerator or recycler.

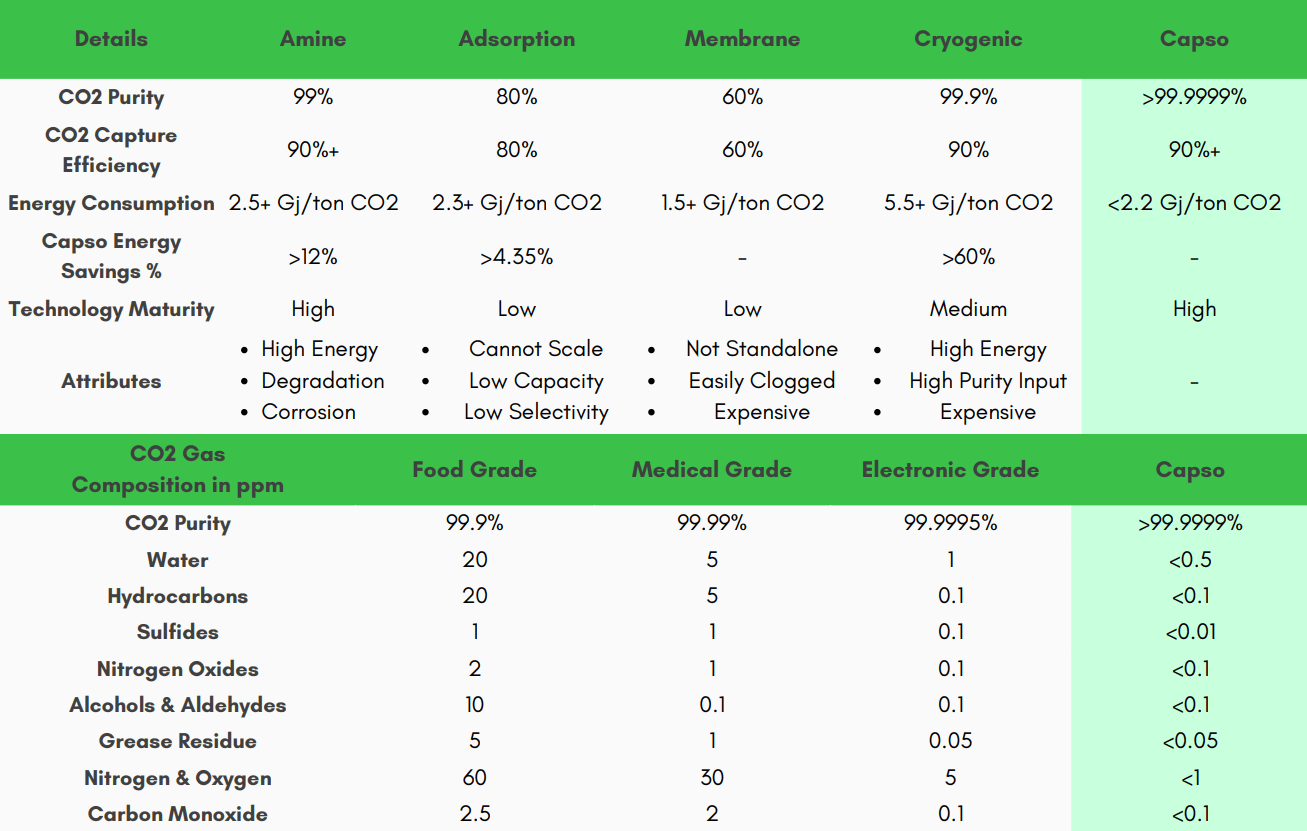

A comparison of CapsoPure with popular post-combustion carbon capture processes, as well as different CO2 purity standards.

Contact Us

Contact us at [email protected] or fill out the form below